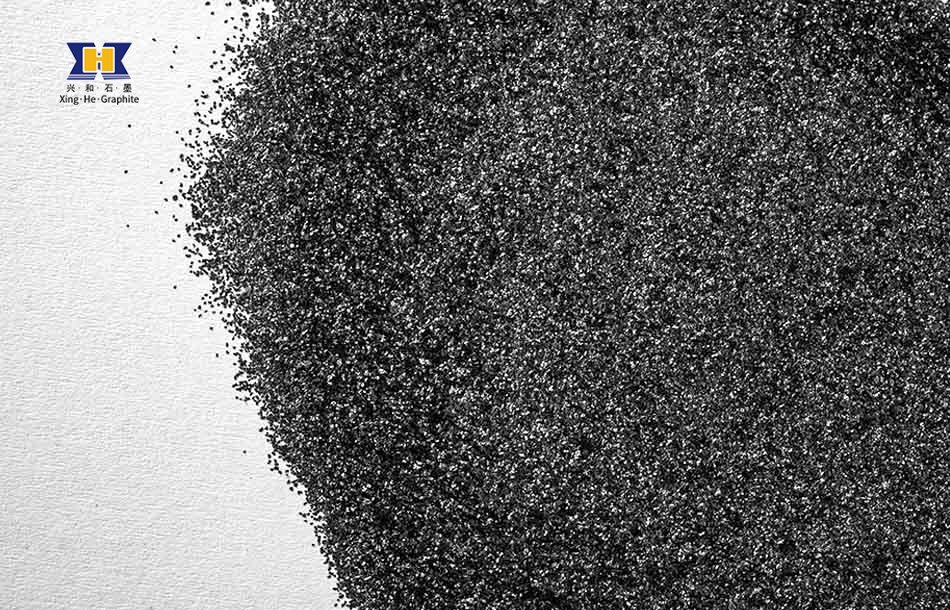

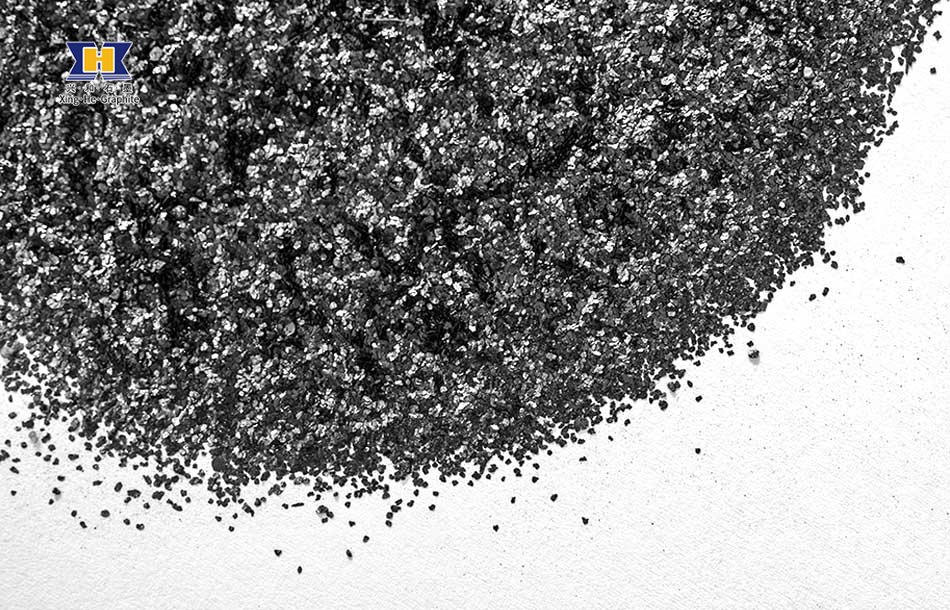

Flake graphite is a natural solid lubricant with a layered structure. It has complete crystallization, thin flakes, good toughness, and excellent physical and chemical properties such as good temperature resistance, self-lubrication, conductivity, thermal shock resistance, and corrosion resistance.

Natural flake graphite has good temperature resistance and can remain stable in high temperature environment. Its layered structure makes the graphite have excellent self-lubricity and can be used as a solid lubricant.

High purity graphite refers to graphite material that has been refined to remove impurities, achieving a carbon content of 99.9% or higher. It possesses excellent mechanical strength. And density and purity are both high, making it an ideal material for various applications.

Micro-powder graphite is a fine, high-purity graphite material often processed to meet specific particle size requirements. It is widely used in various industries due to its excellent properties, such as high-temperature resistance, lubricity, conductivity, and chemical stability.

Remarks:

1) Carbon range: in compliance with customer’s demands from 90% up to 99.99%.

2) Particle size: the average size d50 of “MGF” is available from 4 µm ~ 35 µm; d50 of “MGR” is available from 10 µm ~ 45 µm.

3) Packaging: upon requirements, typically small paper bags or jumbo bags.

4) Raw material base: natural flake graphite.

5) More special graphite series for different applications are available, such as the series for carbon brushes.

6) Our quality is equivalent to European standards.

Colloidal graphite is a stable concentrated colloidal solution formed by the average dispersion of graphite particles below 2μm in an organic solvent. It appears as a black viscous suspended liquid with the properties of high quality natural flake graphite.

Spherical graphite is a vital material in the energy transition, enabling the development of high-performance batteries for electric vehicles and renewable energy storage. As demand for energy storage solutions grows, the importance of SPG in the global supply chain will only increase. Spherical graphite has excellent electrical conductivity and is the core component of negative electrode materials for lithium-ion batteries.

1. Flame Retardant Additive

Expandable graphite is an environmentally friendly flame retardant widely used in:

Building Materials: Added to fire-resistant coatings, paints, and construction boards to prevent fire spread.

Polymers & Plastics: Enhances the flame retardancy of rubber, polyurethane foams, and thermoplastics used in electronics and automotive parts.

Fireproof Fabrics: Used in protective clothing and insulation materials.

2. Sealing and Gasket Materials

Thanks to its excellent heat and chemical resistance, expandable graphite is used in:

Graphite Gaskets: Found in automotive engines, industrial machinery, and petrochemical processing.

Flexible Graphite Sheets: Applied in high-temperature sealing solutions for pipelines, flanges, and valves.

3. Environmental & Energy Applications

Oil Spill Absorption: Helps remove oil and pollutants from water surfaces.

Air & Water Purification: Used in filtration systems to trap contaminants.

4. Foundry & Metallurgy

Expandable graphite is a key material in high-temperature industrial processes:

Refractories & Casting Molds: Protects molten metals from oxidation.

Steel & Iron Industry: Used as an additive to improve thermal stability.

Flake graphite is a natural solid lubricant with a layered structure. It has complete crystallization, thin flakes, good toughness, and excellent physical and chemical properties such as good temperature resistance, self-lubrication, conductivity, thermal shock resistance, and corrosion resistance.

Graphite Grades | Carbon Content (%) | Particle Size | Typical Applications |

WT75-F200 | >75 | max. 20% > 200 mesh | Lubricants, Foundry coating, Friction, Pencil Carburizer |

WT80-F200 | >80 | ||

WT85-F200 | >85 | ||

WT75-F325 | >75 | max. 20% > 325 mesh | |

WT80- F325 | >80 | ||

WT85- F325 | >85 |

Granular artificial graphite refers to a form of artificial graphite that is processed into larger, granular particles. It is typically produced through a high-temperature process known as graphitization, where carbon-rich materials like petroleum coke or coal tar pitch are subjected to intense heat in a furnace, resulting in graphite.

Advantages:

High Performance:

Retains the natural properties of graphite in a convenient liquid form.

Ease of Application:

Can be sprayed, brushed, or dipped onto surfaces for uniform coverage.

Environmentally Friendly Options:

Water-based emulsions are eco-friendly and safer to handle compared to oil-based alternatives.

Customizable Formulations:

Concentrations and additives can be tailored to meet specific industrial requirements.

Delivers consistent results across a wide range of temperatures and pressures.

Graphene is a two-dimensional material composed of a single layer of carbon atoms arranged in a hexagonal honeycomb lattice. It is derived from graphite, the same material found in pencil lead, but graphene exhibits remarkable properties that make it a revolutionary material in many scientific and industrial fields.

As graphene research and production methods advance, it is becoming more accessible and affordable, driving innovation in various fields.